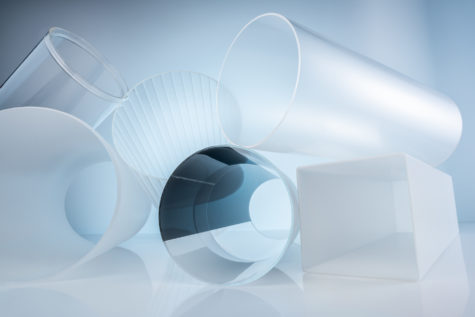

As a manufacturer for visually sophisticated products, we use the extrusion process to produce plastic tubes made of acrylic and polycarbonate for our customers in a wide range of variants and the highest surface qualities. In addition to round and square tubes, we also supply tubes with internal prisms for light control or light diffusion. We adapt the diameter, wall thickness and length individually to your requirements. To minimise your own effort, we will process your acrylic or polycarbonate tubes directly on request – your advantage: unpack and assemble!

We manufacture transparent / clear plastic tubes made of acrylic or polycarbonate with guaranteed fitting accuracy. Different areas of application often require individual properties of the plastic, which is why we adapt the tubes to your requirements. Acrylic or polycarbonate? – We advise you on the selection of the right material for your tube.

Take advantage of the large variety of our standard diameters for your tube of acrylic or polycarbonate to make your project a success quickly and cost-effectively:

Your acrylic or policarbonate tube needs an exact measurement for your application:

Benefit from our adaptive tool technology to realise your individual requirements.

Tube dimension Wall thickness Material

Ø 30 mm 1,5 - 2,0 mm Acrylic, polycarbonate

Ø 40 mm 1,5 - 3,0 mm Acrylic, polycarbonate

Ø 45 mm 1,5 - 3,0 mm Acrylic, polycarbonate

Ø 50 mm 1,5 - 3,0 mm Acrylic, polycarbonate

Ø 60 mm 2,0 - 3,0 mm Acrylic, polycarbonate

Ø 65 mm 2,0 - 3,0 mm Acrylic, polycarbonate

Ø 70 mm 2,0 - 3,0 mm Acrylic, polycarbonate

Ø 80 mm 2,0 - 3,0 mm Acrylic, polycarbonate

Ø 84 mm 2,0 - 3,0 mm Acrylic, polycarbonate

Ø 90 mm 2,0 - 3,0 mm Acrylic, polycarbonate

Ø 100 mm 2,0 - 3,0 mm Acrylic, polycarbonate

Ø 110 mm 2,0 - 3,0 mm Acrylic, polycarbonate

Ø 120 mm 2,0 - 3,0 mm Acrylic, polycarbonate

Ø 133 mm 2,0 - 3,0 mm Acrylic, polycarbonate

Ø 140 mm 2,5 - 4,0 mm Acrylic, polycarbonate

Ø 150 mm 2,5 - 4,0 mm Acrylic, polycarbonate

Ø 160 mm 2,5 - 4,0 mm Acrylic, polycarbonate

Ø 170 mm 2,5 - 4,0 mm Acrylic, polycarbonate

Ø 180 mm 2,5 - 4,0 mm Acrylic, polycarbonate

Ø 190 mm 2,5 - 4,0 mm Acrylic, polycarbonate

Ø 195 mm 2,5 - 4,0 mm Acrylic, polycarbonate

Ø 200 mm 3,0 - 4,0 mm Acrylic, polycarbonate

Ø 220 mm 3,0 - 4,0 mm Acrylic, polycarbonate

Ø 230 mm 3,0 - 4,0 mm Acrylic, polycarbonate

Ø 250 mm 3,0 - 5,0 mm Acrylic, polycarbonate

Ø 273 mm 3,0 - 5,0 mm Acrylic, polycarbonate

Ø 300 mm 3,0 - 5,0 mm Acrylic, polycarbonate

Ø 315 mm 3,0 - 5,0 mm Acrylic, polycarbonate

Ø 324 mm 3,0 - 5,0 mm Acrylic, polycarbonate

Ø 350 mm 4,0 - 5,0 mm Acrylic, polycarbonate

Ø 400 mm 4,0 - 5,0 mm Acrylic, polycarbonate

Ø 450 mm 4,0 - 5,0 mm Acrylic, polycarbonate

Ø 500 mm 4,0 - 5,0 mm Acrylic, polycarbonate

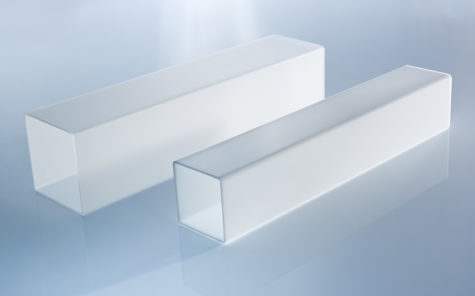

Square tube dimension Wall thickness Material

Side length 45 mm 1,5 - 2,5 mm Acrylic satin

Side length 90 mm 3,0 mm Acrylic satin

Side length 100 mm 3,0 mm Acrylic satin

Side length 120 mm 3,0 mm Acrylic satin

Side length 170 mm 3,0 mm Acrylic satin

We manufacture to order and do not usually stock the listed acrylic and polybarbonate tube variants. Diameters and lengths deviating from the table as well as impact-resistant or coloured variants are available on request. Each tubes is available in the following finisch:

Our many years of production expertise enable us to achieve the clear glass-like appearance of our tubes made of acrylic and polycarbonate. To do this, we use the engineering plastics polycarbonate (e.g. Makrolon®, Lexan®) and polymethyl methacrylate (e.g. PLEXIGLAS®, Altuglas®).

This combination guarantees the consistent high quality of our transparent / clear acrylic and polycarbonate tubes with their outstanding properties.