Our expertise in plastics processing includes not only the production of customised drawing parts from sheet material, but also the further processing of our own extruded tubes and profiles. In this way, even complex components are created entirely according to your specifications, sometimes in several work steps.

We have the most modern machines, such as precision saws, milling machines or 5-axis and 3-axis CNC machining centres.

Our continuously trained and qualified employees are specialists in the processing of plastics. This includes activities such as gluing, polishing, foiling, ultrasonic welding, milling and laser cutting of plastic parts of all kinds.

In short: We manufacture ready-made parts of the highest quality for you from a single source – Made in Germany!

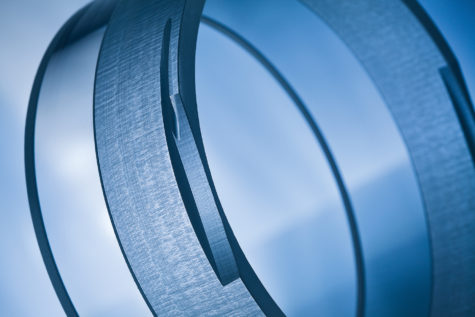

As a manufacturer of tubes and profiles, we have long been your reliable partner in the field of plastic extrusion. In order to meet all the needs of our customers, we offer not only standard lengths, but also the right cut for them as a tube cylinder or profile piece.

Benefit from our know-how by having us deliver your plastic components ready for assembly. Your Benefit: Don’t worry about cutting or time-consuming mounting holes. We will gladly take over these individual processing steps – and you can concentrate fully on your core competencies.